Table of Contents

T16: Effect of microstructure and conditions (Part 2)

This tutorial was tested on

MatCalc version 6.04 rel 1.001

license: free

database: mc_fe.tdb; mc_fe.ddb

Complimentary files

Click here to view the script for this tutorial

Contents:

- Simultaneous precipitation of two phases

- Effect of dislocation density

- Effect of grain diameter

- Subgrains and elongation factors

Before starting...

Re-open the workspace saved from Tutorial 15 and save it under a new name.

Simultaneous precipitation of cementite and M<sub>23</sub>C<sub>6</sub>

Setup

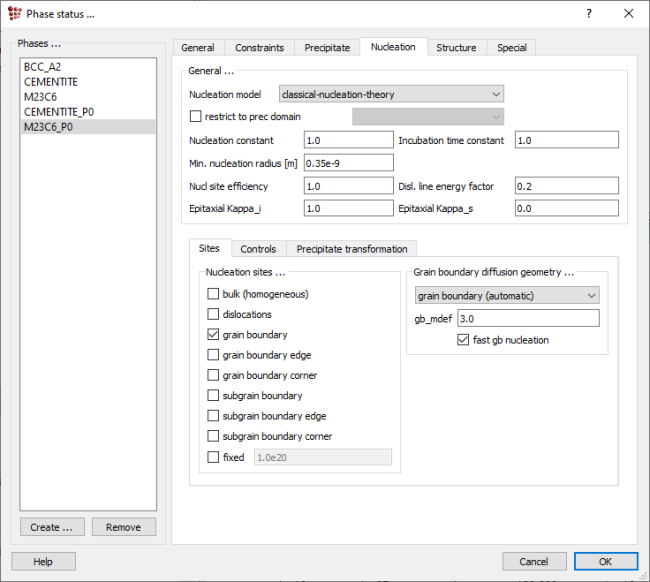

Open 'Global > Phase status' and create a precipitate phase from M23C6. In the 'Nucleation' tab, set the nucleus composition model to 'ortho-equilibrium'. Set the nucleation sites to 'Grain boundaries' in the 'Nucl. sites' tab.

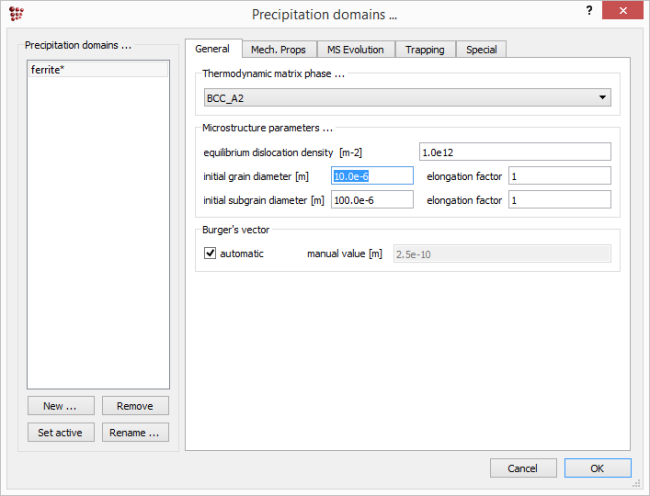

In 'Global > Precipitation domains > General', reset the dislocation density to its default value of '1e12' m-2. The default grain diameter is '100e-6' m, and it is this which governs the density of M23C6_P0 nucleation sites. Modify the existing five plots to contain the following series:

- F$CEMENTITE_P0, F$M23C6_P0 (fraction of cementite and M23C6 precipitated, respectively)

- XPR$CEMENTITE_P0$CR, X$BCC_A2$CR (Cr content of cementite precipitates and matrix, respectively)

- X$BCC_A2$C (C content of matrix)

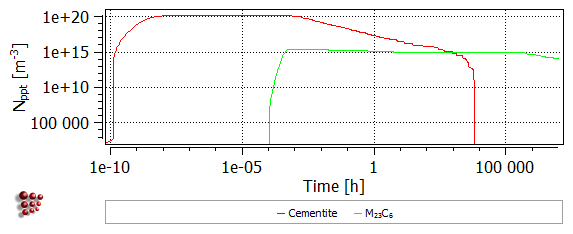

- NUM_PREC$CEMENTITE_P0, NUM_PREC$M23C6_P0 (number of cementite and M23C6 precipitates, respectively)

- R_MEAN$CEMENTITE_P0, R_MEAN$M23C6_P0 (mean radius of cementite and M23C6 precipitates, respectively)

Run the kinetic simulation, with an isothermal heat treatment at 600°C as before, and an end time of 3.6e+10 s.

Interpretation of results

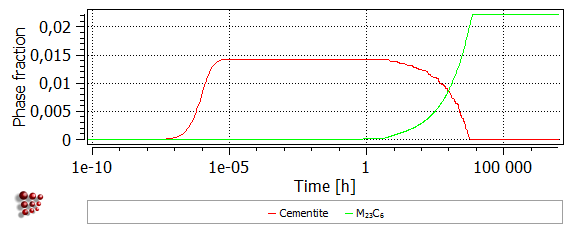

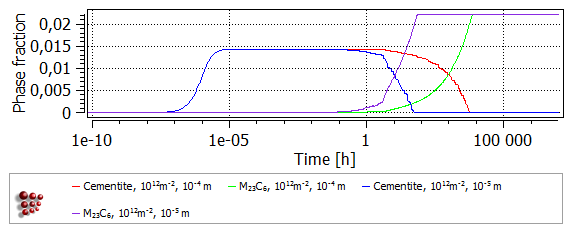

Plot 1: Cementite appears rapidly and reaches a steady-state precipitate fraction. M23C6 starts to form after around 1 hour at 600°C; this is at the expense of cementite, which redissolves. By the end of the simulation, all the cementite has dissolved and M23C6 has reached its equilibrium phase fraction.

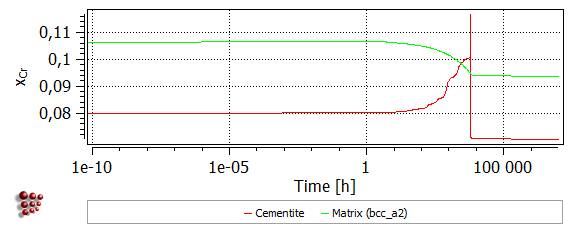

Plot 2: This shows that cementite enrichment has started in the time of the cementite dissolution.

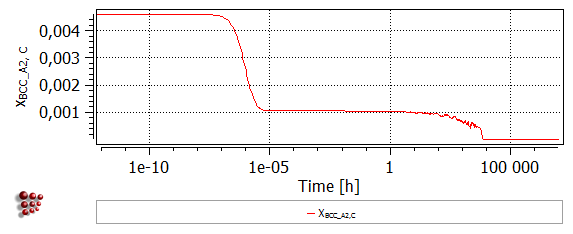

Plot 3: The depletion of the matrix in carbon occurs in two stages. The first of these corresponds to the formation of cementite, and the second to the formation of M23C6.

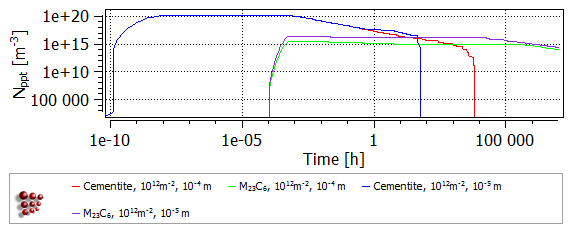

Plot 4: The number of M23C6 precipitates is lower than the one cementite precipitates which is due to the lower amount of the nucleation sites - there are less sites on the grain boundaries than on the dislocations. The reduction in the number of cementite precipitates is both due to the coarsening and the phase dissolution stages:

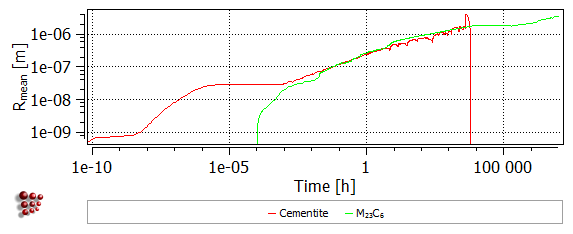

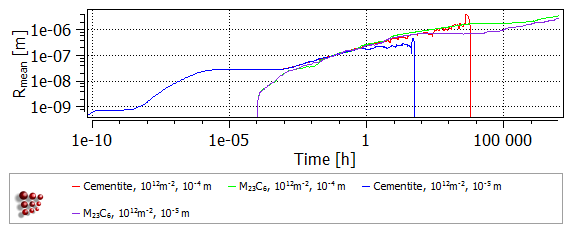

Plot 5: There is an intermediate stage between the growth and coarsening phases for the cementite precipitates (plateau between 10-6 - 10-3 hours). The maximal size of the cementite precipitates is in the micrometer range.

Effect of dislocation density

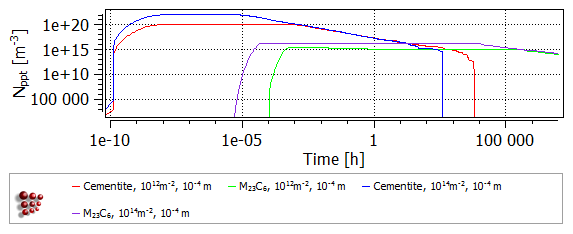

Duplicate and lock the series and re-run the simulation with a dislocation density of 1e14 m-2, leaving the grain size the same.

Results:

The onset of cementite precipitation occurs earlier with a higher dislocation density, but the kinetics of cementite dissolution and of M23C6 precipitation are unchanged. The plot below shows a significant increase (note log scale) in the number of cementite precipitates formed.

With a higher dislocation density, the cementite particles do not become so large during the growth stage. However, coarsening begins earlier, and the curve of radius versus time for the coarsening precipitates eventually becomes parallel with that for the lower dislocation density.

Effect of grain diameter

Reopen 'Global > Precipitation domains > General'. Reset the dislocation density to 1e12 m-2, set the grain diameter to 10e-6 m and re-run the simulation.

Results:

As might be expected, reducing the grain diameter accelerates the precipitation kinetics of M23C6, by providing more nucleation sites. It also accelerates the dissolution of cementite, which begins to dissolve when M23C6 starts to precipitate.

The plot below shows the effect on the number of M23C6 of reducing the grain size from 10-4 to 10-5 m. The number of M23C6 increased due to more nucleation sites available.

In the plot of radius against time, the maximum cementite radius attained is reduced, because there is less time available for coarsening of this phase before dissolution sets in.

Consecutive articles

The tutorial is continued in article T17 - Multi-stage heat treatment

Go to MatCalc tutorial index.