Table of Contents

Example P20: Precipitation simulation during continuous casting of micro-alloyed Fe-Al-C-N-Nb-Ti steel, part 1: Treatment of primary precipitates

Compatibility

MatCalc version: 5.61.1000 (click here if you use an older version)

Database: mc_fe.tdb, mc_x_FeAlCNNbTi.tdb, mc_fe.ddb

Author: G. Stechauner

Created: 2011-11-23

Revisions: 2015-02-13 (P. Warczok)

Objectives

This is the first of two parts, which describe how to deal with primary precipitates. It is shown how the precipitate phases with the desired size and number density are created based on the Scheil-Gulliver calculation results. This calc state is then used for further calculation of the 'real' heat treatment.

Part one starts off with a Scheil-Gulliver analysis to obtain the phase fraction and chemical composition of the primary precipitates. Next, the phase fraction and chemical composition information is transferred into the relevant precipitate phases. With this method, an adequate calc state is found, which can be used for further precipitation calculations.

Part two will continue with the calculation of precipitation in enriched and depleted regions.

Related documents

- 'HowTo' manual - Primary precipitates

Complementary files

Click here to view the script for this tutorial.

Main document

Consider the same microalloyed steel as in example E20. The following table summarizes the chemical composition of the steel used in this study. The nominal composition is given in wt%.

| C | Al | N | Nb | Ti |

|---|---|---|---|---|

| 0.22 | 0.025 | 0.0061 | 0.036 | 0.0081 |

Setup thermodynamics

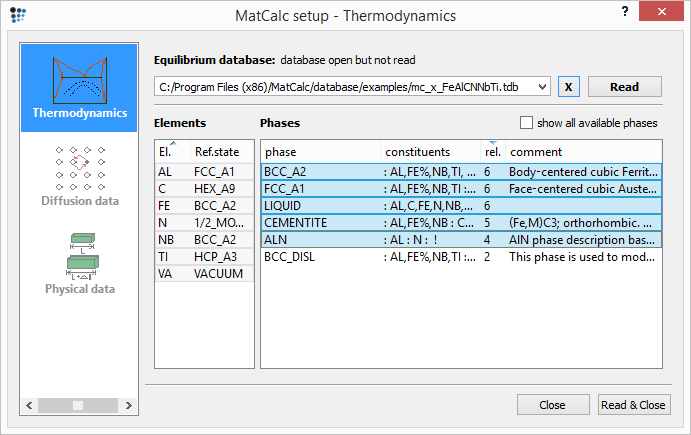

For simulation, either the 'mc_fe' or the 'mc_x_FeAlCNNbTi' database can be used. The dialog below shows the selected elements and phases for the 'mc_x_FeAlCNNbTi' database:

Open the database, select elements and phases, and read the database. Further load the diffusion database for Fe, as it is needed in precipitation simulation. Then enter the composition of the system in the 'Composition …' dialog of the 'Global' menu according to the table shown above.

Setup phases

With the selection of the FCC_A1 phase, MatCalc automatically creates a complex carbo-nitride if Nb and Ti as well as C and N are selected. This complex carbo-nitride shows a miscibilitiy gap, however, which must be taken into account in the simulation setup. This issue is dealt with extensively in example E3 - Analysis of the miscibility gap in Fe-C-N-Nb-V. The carbo-nitride phase FCC_A1#01 is separated into two phases in the following steps: Suspend the original complex phase. Create composition sets for the miscibility gap phases.

Open the phase status dialog window and suspend the automatically created FCC_A1#01 in the 'general' tab. Select the FCC_A1 phase and create a composition set by pressing the 'Create…' button. Select 'composition set', instead of 'equilibrium'. Enter :NB%,TI:C%,N,VA: as constituents for NbC and name it correspondingly. Repeat this procedure for TiN and define the constituents and major constituents (by setting the %) appropriately (:NB,TI%:C,N%,VA:).

Evaluate phase fraction of primary precipitates

Perform a Scheil-Gulliver analysis to obtain the values for phase fraction and chemical composition of primary precipitation phase. Refer to E20 if you want to refresh your knowledge about this method.

Choose a temperature of 1570°C to start the Scheil simulation in the liquid phase. Allow back-diffusion of C and N and run the calculation to a minimum liquid fraction of 3% (enter as 0.03).

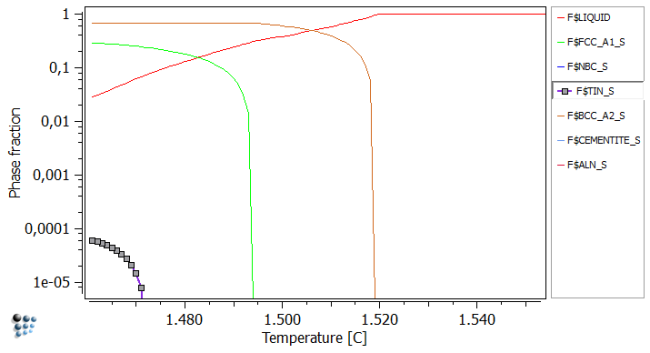

Plot the liquid and Scheil-Phase fractions in an X-Y plot. After renaming, rescaling, and zooming in, a figure similar to the one below should be obtained.

The easiest method to extract the chemical composition of the solute-enriched region now is, to open the Buffer states window (Ctrl + L) and select the temperature corresponding to 3% residual liquid. This is generally the lowest temperature, or the one above it. In our case, we use the temperature of 1462°C as the phase fraction of liquid is closer to the 3% compared to the values obtained at 1461°C.

Phase fractions obtained at 1462°C:

#### /LIQUID/ moles: 0,0305076, gm: -101295 (-101295), sff: 1 Phasestatus: entered - active FE +9,52351e-001 C +4,18904e-002 NB +4,28714e-003 TI +7,14451e-004 N +5,35481e-004 AL +2,21249e-004 #### /TIN_S/ moles: 5,64144e-005, gm: -226949 (-226949), sff: 0,500378 Phasestatus: fixed dfm: -9,46075e+000 TI +4,94450e-001 N +4,46308e-001 C +5,33139e-002 NB +5,92815e-003

Now that we know the phase fraction and chemical composition of the primary TiN, we can create the primary precipitate phase based on it.

Important note …

Introduction of the primary precipitate population

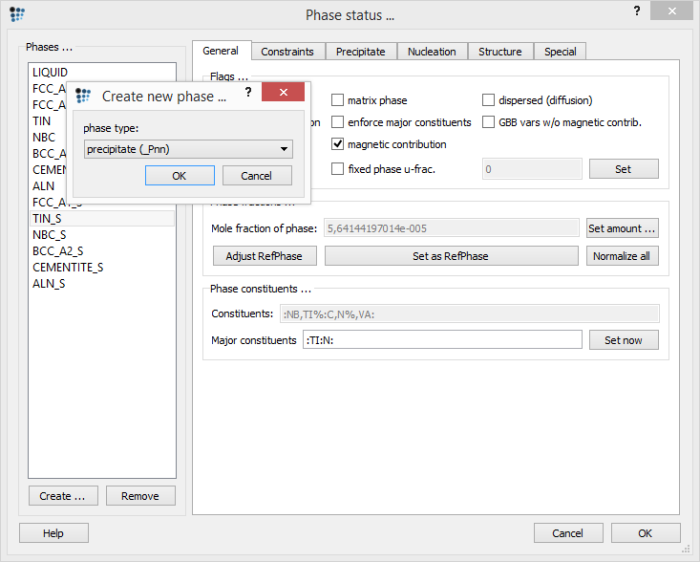

Having found the estimated phase fraction and chemical composition of the primary TiN preciptate, this information can be transfered into the precipitate phase. First, select the TIN_S phase and create a preciptate phase from it.

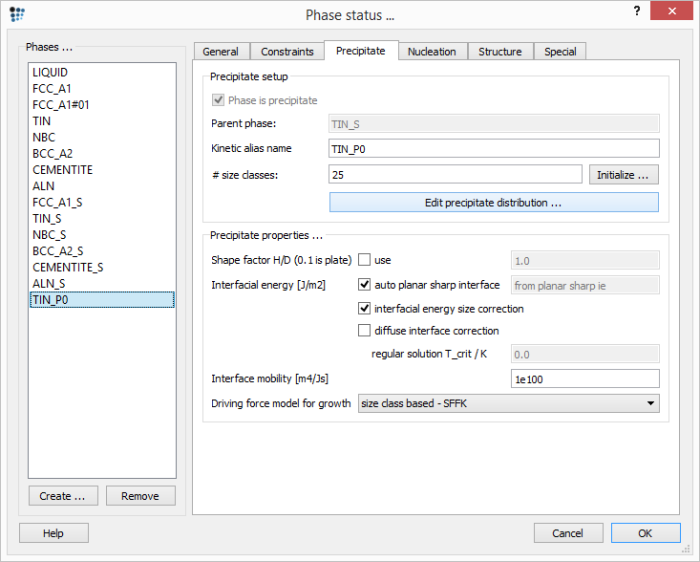

Now, rerun the Scheil calculation. When done, load the buffer state for 1462°C again - click on 'load selected' in 'Edit and load buffer states…' window. In the 'phase status' window, select this new precipitate phase, and edit the precipitate distribution (click on the corresponding button in 'Precipitate' tab)

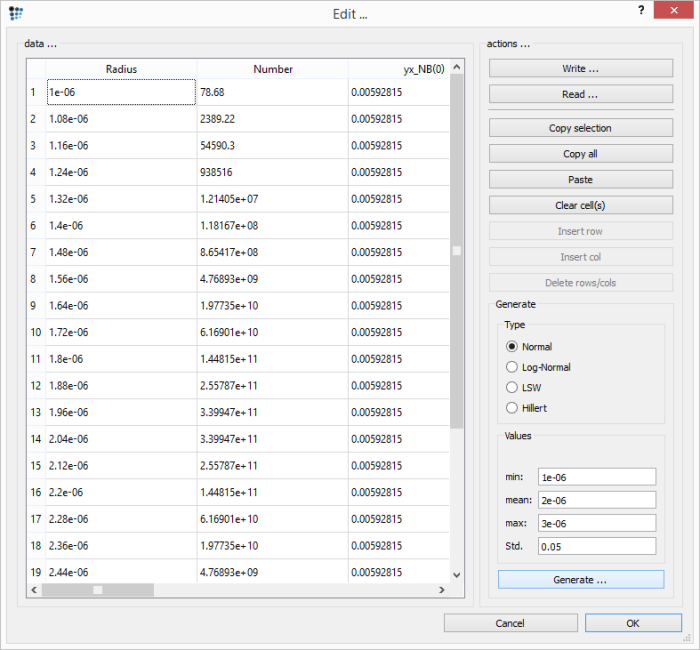

Let's have a look on the 'Generate' area of the appearing 'Edit…' window. It contains the settings for the precipitate distribution generation. First, a type of the distribution can be selected. Second, the parameters for the preciptate sizes can be defined. The default settings create a preciptate phase with a normal size distribution within the 1-3 micrometer radius limit and the mean radius of 2 micrometers. These match the expectation of the primary precipitate in the system. Click on 'Generate…' button.

Click on 'OK' and accept the changes mentioned in the appearing dialog box

Setting up the precipitation system

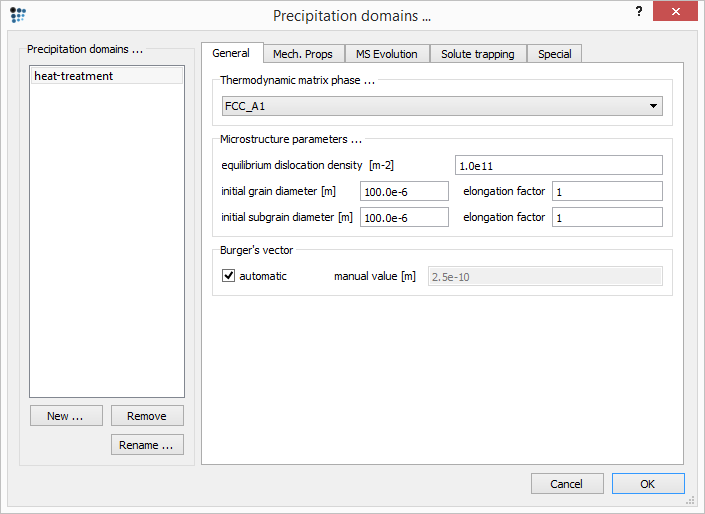

Create a precipitation domain 'heat-treatment' and select the FCC_A1 phase as the matrix phase.

Continue by defining the precipitates:

- Create another precipitate phase for

TiN(with '_P1'-suffix) and one for eachNbCandAlN(with '_P0'-suffices) - This time use equilibrium phases as the parent phases. - Enter the following values in the 'precipitate' tab of the 'phase status' dialog:

| Precipitate | TiN_p0 | TiN_p1 | NbC_p0 | AlN_p0 |

|---|---|---|---|---|

| nucleate only with valid major const. | - | ✔ | ✔ | ✔ |

| nucleation site | none | dislocations | dislocations | dislocations |

Create new calculation state with the name 'initial'

Transfer of precipitate distributions

Save the workspace file as 'P20_1.mcw'.

Once we have generated the size distribution for the primary precipitate, we can export the size distribution into a file to be able to read it back into our system in the further simulations. To do so, open the 'phase status' dialog in the precipitate tab and click the 'edit precipitate distribution' button. Use the 'Write …' button to export the size distribution into a text file. Give it the name 'size_dist_tin_primary.txt'.

Alternatively, you can save the size distribution using console command:

EXPORT_PRECIPITATE_DIST tin_p0 size_dist_tin_primary.txt

Consecutive articles

This analysis is continued in part 2 article Precipitation kinetics in segregated and depleted regions